The Basic Principles Of Paper Machine

Wiki Article

More About Paper Machine

Table of ContentsSome Ideas on Paper Machine You Should KnowPaper Machine for BeginnersThe Only Guide for Paper MachineThe Only Guide to Paper MachineThe smart Trick of Paper Machine That Nobody is Talking AboutOur Paper Machine Statements

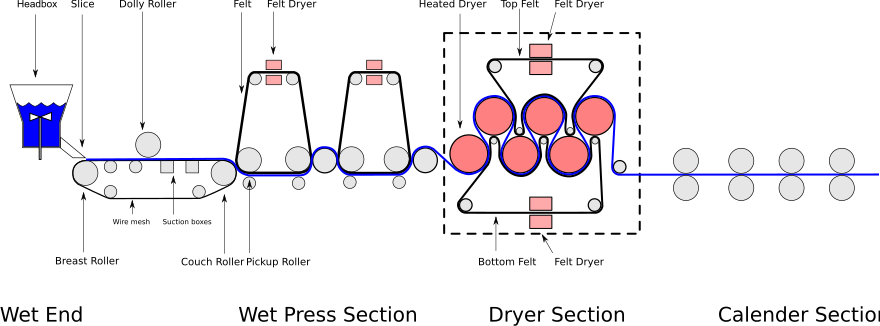

The fundamental procedure is an industrialised variation of the historical procedure of hand paper-making, which can not please the demands of establishing modern culture for large quantities of a printing and writing substratum. The initial modern-day paper maker was developed by Louis-Nicolas Robert in France in 1799, and an improved variation patented in Britain by Henry and Sealy Fourdrinier in 1806., where the damp fibre internet passes between large rolls filled under high pressure to press out as much water as feasible.

Drying out eliminates the water content down to a degree of regarding 6%, where it will certainly remain at typical interior atmospheric problems., where the dried paper is smoothened under high loading as well as pressure.

Paper Machine Can Be Fun For Anyone

The sheet was after that raised off to be hung over a rope or wood rod to air completely dry. In 1799, Louis-Nicolas Robert of Essonnes, France, was provided a patent for a continual paper making equipment. At the time, Robert was helping Saint-Lger Didot, with whom he quarreled over the possession of the invention.

With the aid of Bryan Donkin, a skilled as well as ingenious mechanic, a boosted variation of the Robert original was mounted at Frogmore Paper Mill, Apsley, Hertfordshire, in 1803, complied with by another in 1804. A 3rd equipment was set up at the Fourdriniers' very own mill at Two Seas. The Fourdriniers likewise bought a mill at St Neots planning to set up two machines there, and also the process and devices remained to develop.

Rumored Buzz on Paper Machine

The method of constant manufacturing demonstrated by the paper machine influenced the growth of constant rolling of iron as well as later on steel and various other continual manufacturing procedures. The plant fibers made use of for pulp are made up mainly of cellulose and hemi-cellulose, which tend to form molecular affiliations between fibers in the existence of water.

A cylinder with cutting edges, or blades, as well as a knife bed is part of the loop. The rotating cylinder pushes the components of the trough around repeatedly. As it reduces gradually over a period of hrs, it damages the rags up right into fibers, and reduces the fibers to the preferred size.

Paper Machine for Dummies

An additional resource of cotton fibre originates from the cotton ginning procedure. The seeds remain, surrounded by brief fibers called linters for their brief size and also resemblance to lint. Linters are as well brief for effective use in fabric. Linters eliminated from the cotton seeds are offered as first and 2nd cuts.Kraft pulp has exceptional stamina to sulphite and also mechanical pulps as well as kraft procedure invested pulping chemicals are less complicated to recoup and also regenerate. Both chemical pulps as well as mechanical pulps might be bleached to a high brightness.

Lignin, like many various reference other substances that can separate fibres from one an additional, acts as a debonding agent, decreasing strength. blog Stamina also depends on maintaining lengthy cellulose molecule chains.

The Definitive Guide to Paper Machine

It is commonly mixed with virgin pulp - paper machine. At incorporated pulp as well as paper mills, pulp is typically saved in high thickness towers prior to being pumped to stock prep work. Non integrated mills make use of either completely dry pulp or wet lap (pushed) pulp, typically obtained in bundles. The pulp bundles are slushed in a [re] pulper.Printing on reverse side of a sheet will not sidetrack from web content on the obverse side of the sheet.

Top Guidelines Of Paper Machine

From there it is generally watered down to concerning 4% consistency prior to being pumped to a raw stock breast. From the unrefined stock upper body supply is again pumped, with consistency control, with a refiner. Refining is a procedure wherein the pulp slurry passes between a set of discs, one of which is fixed and the various other rotating at speeds of commonly 1,000 or 1,200 RPM for 50 and 60 Hz AC, specifically.This activity untangles the external layer of the fibers, causing the fibrils of the fibers to partially separate as well as bloom exterior, raising the surface to promoting bonding. Refining hence increases tensile stamina. Tissue paper is reasonably unrefined whereas product packaging paper is more very refined. Fine-tuned stock from the refiner then goes to a refined supply chest, or mix chest, if used as such.

Report this wiki page